Two-Pronged Approach to LED Manufacturing

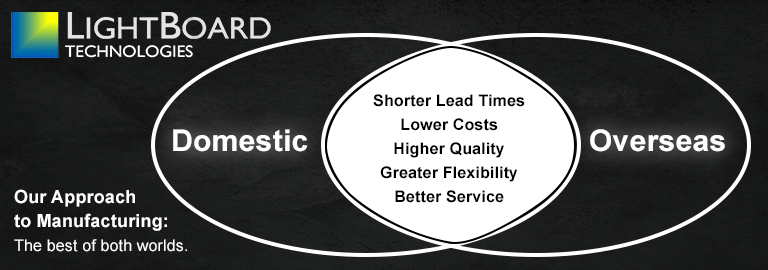

We continually strive to provide LED light solutions that offer the best value for our customers. As part of this effort, we divide our manufacturing capabilities across multiple facilities, both domestic and overseas, for a two-pronged approach providing greater flexibility, shorter lead times, and better service.

Our primary facility, located in Golden Valley, Minnesota, houses our design and engineering team. Here, we design lighting solutions of various configurations, construct prototypes, and provide all of our custom engineering services.

Additionally, our full-time production team provides numerous value-add services. Some examples include preparing LED strips for custom applications, building wire harnesses, constructing and reconfiguring lighting assemblies to meet specs, and assembling light panels. Our team includes experts in many areas, including soldering, light panel assembly, testing, and lean production processes.

But not all of our manufacturing is done domestically. Five years ago, we made the decision to co-own a manufacturing facility based in Shenzhen, China. This is where many of our LED strips and supporting products are manufactured. Our ownership role allows us to direct engineering and manage production in ways unavailable to casual consumers.

Excellence in Quality, Lead Time and Cost

With an established infrastructure and a well-developed capacity for production, China-based manufacturers are a time-tested resource for the LED industry.

Our Shenzhen facility features large-scale precision manufacturing equipment such as a high-speed, precision SMT placement system, robotic soldering and optoelectronic inspection. Operating this efficient fabrication equipment here, instead of domestically, greatly reduces costs while ensuring commercial-grade quality.

Ownership also gives us the ability to manage the manufacturing process, from initial design through final testing, an important aspect to ensure overall product quality. We maintain a strong, top-to-top relationship with our manufacturers in China, which strengthens the partnership while providing opportunities for feedback and idea exchanges for optimal quality and breadth of product offerings.

Manufacturing abroad is not without challenges, and lead time and fulfillment can be a customer concern. Ownership allows us to prioritize production schedules and optimize timelines to meet tight deadlines. Also, our team is experienced in importing product from China and thoroughly understands freight options that can offer savings in both time and costs in shipping.

Future Developments

Hybridizing production in USA and China ensures we provide our customers with commercial-grade LED products delivered on time and at a great value. To continue offering these advantages to our customers, we’re dedicated to the ongoing search for the best balance of manufacturing resources to achieve the best quality and value in LED lighting solutions.

Future changes may lead us to other models and places of production. There are certainly regions in Southeast Asia that may rise to offer a better overall product value in the future. Until then, we — and most importantly, our customers — are pleased with the results of our mix of manufacturing both domestically and overseas.