#LightLearning: the Language of Light Measurement

Light is a universal experience, but not a simple one. In fact, it’s one of the most complex phenomena we experience, and understanding lighting measurement can go a long way to ensuring a successful project.

To help our customers explore the complex language of light measurement, we called on our knowledgeable Engineering Advisor—Brad Klassen. Read on to explore his first piece in our new series: #LightLearning.

— Team at LightBoard Technologies

The Importance of Understanding LED Lighting for Retail Fixtures

Lighting is measured in many different ways, with a lot of technical terms thrown around: lux, lumens, foot candles, color temperature and more. These terms are often used incorrectly or interchangeably, to the detriment of clarity. Depending on the discipline, light might be measured in watts, lumens, candelas, foot candles, nits…

Complicating matters further, a retail fixture project can have a large number of employees contributing, creating a game of telephone between managers, designers, consultants and the production team. A basic understanding of lighting terminology can go a long way to eliminating confusion, delays and possible errors.

Some Basic Terms

Radiometric measurements: the measure of light energy without regard to how our eye perceives it

Photometric measurements: the measurement of visible light energy as our eye perceives it

Spectroradiometric measurements: the measurement of light energy at specific wavelengths (colors) without regard to how our eye perceives it.

Electrical measurements: the measurement of Electromagnetic energy not limited to light

Most of the time our customers are interested in how the light appears to the human eye, and how to power the lights electrically. In the case of how bright the display is this means that the measurements will be in Photometric units and Electrical units of measure.

The Language of Light Measurement

In order to understand Photometric measurements, consider the following:

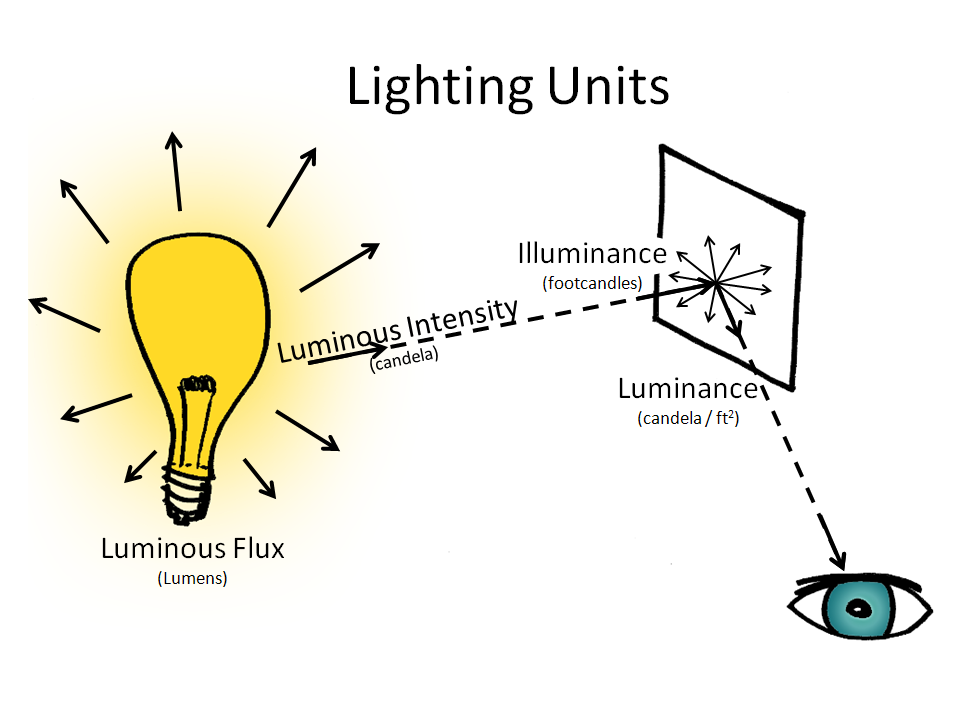

Light at its source is its Intensity (I) and is measured in Candelas (cd) and originated from the light of a wax candle. It’s value is dependent mostly on direction, not distance. Think of looking at a candle or a lightbulb.

Light traveling through space is its Flux, is measured in Lumens and is dependent on the size of the frame that the light is passing through. One candela passing through one square foot is one lumen. The size of the frame is technically called the solid angle; it is the measure of total light energy considering the effects of geometry.

Light density on a surface is Illuminance and is measured in Lux (lumens per square meter) or Footcandles (lumens per square foot), is dependent on distance and angle of incidence. Think of a flashlight on a wall with the light on the wall getting brighter as you bring it closer, and dimmer with distance and the angle that you shine it at.

Total light reflected off a surface is Exitance and can be thought of similarly to illuminance, with the addition of how reflective the surface is. Think of a white surface which appears brighter than a black surface.

The specific light reflected off a surface is Luminance and is measured in Candelas per square foot. This measurement takes account of the light’s direction and how much surface diffusion is present. Think of it like a flat painted wall versus a mirror—a surface property known as specularity.

There are a lot of concepts and terms just to describe what we call brightness. In practice, it is wise to limit communications to the light density measurement (illuminance) because measurement tools are widely available and affordable, each of the other measurements require extensive test setups and much more expensive test equipment to measure, they are also largely irrelevant to the end result in the retail fixture environment. Lumens are particularly often misapplied to retail fixture lighting.

Fortunately, the Electrical measurements are much more straightforward. The total electrical power we need is measured in Watts and is the product of the voltage and the current, 1-volt X 1 amp = 1 Watt. From this we can determine Power Supply and Wiring requirements and UL compliance.

What About Color?

If brightness is complex, it pales to the complexity of color. Fortunately, in retail lighting we can typically use white light and limit our communication to Color Temperature for light boxes and edge- or perimeter-lit fabric displays.

As you are probably aware, light is made up of different colors of light that are different frequencies or wavelengths the same as bass and treble sounds are different frequencies, when light passes through a prism the spectrum from violet to red is the different wavelengths of light.

Color Temperature or Correlated Color Temperature (CCT) is a simplified way to convey the appearance of white light based on the distribution of energy in the various wavelengths of light that combine to make the white light. CCT covers a scale of light form Warm White, think candlelight or a campfire with lots of red light to Cool White, think a bright clear day with lots of blue light.

CCT is measured in degrees Kelvin, with Warm White having lower values (2700 degrees Kelvin), than Cool White 6500 K. These number are the temperature that an ideal nonreflective object would appear if heated to that temperature measured in degrees Kelvin, think of the terms red hot, or white hot. An interesting fact about human vision is that a wide variety of combinations of colors of light will appear as the same color, this is the correlated in CCT.

Lightboard Technology’s experience has shown that the vast majority of backlit, edge lit, and perimeter lit applications are best served by Cool White 6500K light.

A second color metric is Color Rendering Index (CRI) which relates to luminance—the light reflected off an object—as with use of shelf lighting or a product glorifier. LEDs are narrowband devices meaning that they produce a single color of light over a very small number of wavelengths. In order to make white light, phosphorescent material is placed over a blue LED chip. These materials absorb some of the blue light energy and reradiate it at longer wavelengths to produce green, yellow, orange and red light.

The amount of phosphor and composition of the phosphor determine the relative amounts of different color light controlling the CCT, but also the amount of light at various colors to be reflected from the object. The amount of particularly red light is often too little to make red objects appear vibrant. CRI is a number that indicates how well the light will be able to make an object appear appealing. Typically values are 70, 80 and 90, with the higher numbers indicating a better result.

What’s Next?

This overview of LED light measurement for retail applications shows each lighting situation is different. We welcome the opportunity to discuss the subject in greater depth for your specific project.

Email us at info@lightboardtech.com or call 763.205.2412.

LightBoard Technology is a privately held LED lighting technology development company that focuses on the in-store display marketplace. Peter Sussman, who is considered an innovative entrepreneur and a self-made expert in LED lighting solutions for display lighting, founded LightBoard Technologies in 2010. The LightBoard Technologies research, marketing, and product development campus is located in Golden Valley, MN, USA.